Writers: Tiago Delbrücke; Rogério A. Gouvêa; Mário L. Moreira; Cristiane W. Raubach; José A. Varela; Elson Longo; Margarete R.F. Gonçalves; Sergio Cava

Keywords: Sintered porous body; Chemically synthesized; Replica method in organic matrix; Al2O3; Thermal properties

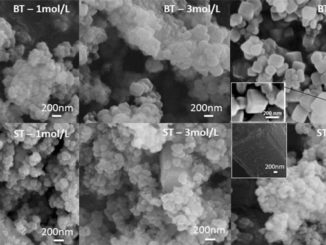

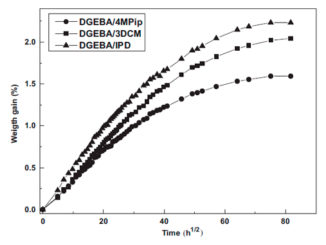

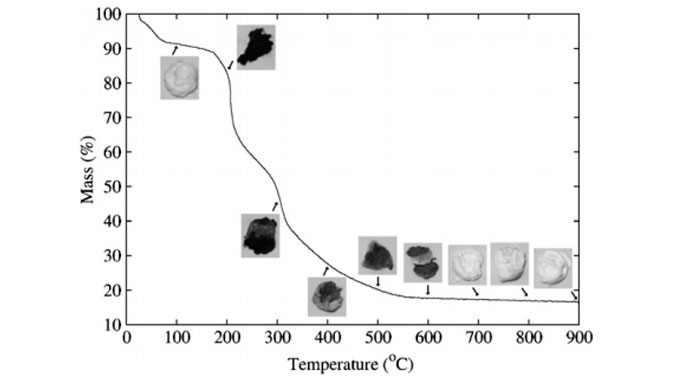

Abstract: In this research report, a sintering process of porous ceramic materials based on Al2O3 was employed using a method where a cation precursor solution is embedded in an organic fibrous cotton matrix. For porous green bodies, the precursor solution and cotton were annealed at temperatures in the range of 100–1600 °C using scanning electron microscopy (SEM) and thermogravimetric (TG) analysis to obtain a porous body formation and disposal process containing organic fibers and precursor solution. In a structure consisting of open pores and interconnected nanometric grains, despite the low porosity of around 40% (calculated geometrically), nitrogen physisorption determined a specific surface area of 14 m2/g, which shows much sintering of porous bodies. Energy dispersive X-ray (EDX) and X-ray diffraction (XRD) analytical methods revealed a predominant amount of α-Al2O3 in the sintered samples. Thermal properties of the sintered Al2O3 fibers were obtained by using the Laser Flash which resulted in the lower thermal conductivity obtained by α-Al2O3 and therefore improved its potential use as an insulating material.

See PDF: Sintering of porous alumina obtained by biotemplate fibers for low thermal conductivity applications

DOI: 10.1016/j.jeurceramsoc.2012.11.009