Writers: Luanna Silveira Parreira; Júlio César Martins da Silva; Melina D’Villa -Silva; Fernando Carmona Simões; Samara Garcia; Ivanise Gaubeur; Marco Aurélio Liutheviciene Cordeiro; Edson Roberto Leite; Mauro Coelho dos Santos

Keywords: Ethanol oxidation; PtSnNi/C electrocatalysts; Accelerated stress tests

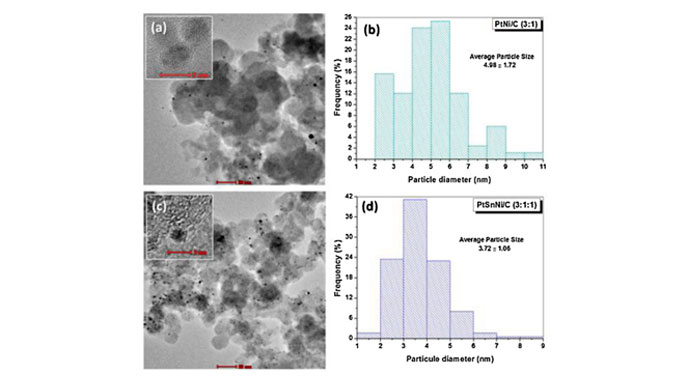

Abstract: This work describes the use of Pt3Sn/C, Pt3Ni/C and Pt3SnNi/C nanoparticle electrocatalysts with a 20% metal loading on carbon prepared using the polymeric precursor method for the ethanol oxidation reaction (EOR). XRD measurements revealed the presence of segregated Pt and NiO phases in the Pt3Ni/C electrocatalysts, whereas for Pt3SnNi/C, there was some evidence that Ni and Sn atoms are incorporated into the Pt structure with the presence of segregated SnO2 and NiO phases. The mean crystallite sizes were 3.6, 5.7 and 7.2 nm for Pt3Sn/C, Pt3Ni/C, and Pt3SnNi/C, respectively. The onset oxidation potential obtained for the EOR using Pt3SnNi/C was close to 0.22 V. Chronoamperometric measurements revealed that the highest current densities for the EOR were obtained using the Pt3SnNi/C nanoparticle electrocatalysts (16 mA mgPt−1). Based on the Ni accelerated stress tests, this element was more stable in the ternary material. In contrast, there was a change in the product formation pathways before (acetaldehyde and acetic acid were the primary products) and after the accelerated stress tests (acetaldehyde was the primary product) for the Pt3SnNi/C catalyst. The experimental results indicate that the Pt3SnNi/C electrocatalysts exhibited better electrocatalytic activity compared to the other electrocatalysts for the EOR. It is suggested that this activity is related to the presence of Ni, which can modify the electronic structure of Pt and combine with Sn to facilitate the removal of adsorbed CO on the surface of the Pt, thereby promoting the EOR.

See PDF: PtSnNiC nanoparticle electrocatalysts for the ethanol oxidation reaction Ni stability study

DOI: 10.1016/j.electacta.2013.02.054