Writers:

Keywords: semiconductors; films; hematite

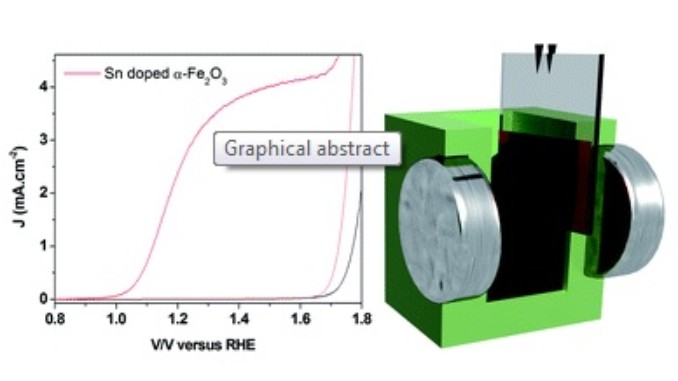

ABSTRACT: Hematite is one of the most promising semiconductors used to convert solar irradiation directly into chemical energy (molecular hydrogen and oxygen) via water splitting. Although several methods have been developed in the last decades, the repertoire of a method to fabricate hematite electrodes with a large covered area, relative low cost, industrial viability and remarkable properties still remains a challenge. This paper describes a microwave-assisted hydrothermal process to produce hematite films. The photoelectrodes prepared consisted of rods of hematite on the FTO substrate (FTO-fluorine doped tin oxide) forming mesoporous nanostructured. According to the X-ray diffraction data, thin films thermally treated at high temperature grew preferentially to the [110] direction, i.e., growth perpendicular to the substrate. Moreover, high temperature of thermal treatment influenced positively on the stability, current density and charge transfer efficiency of photoelectrodes. The impedance spectroscopy (EIS) data aided us to understand the best photoelectrochemical performance exhibited by hematite electrode synthesized during 2 h with additional thermal treatment at 750 °C. The high temperature treatments seem to promote higher ND (charge density) and Vfb values estimated from EIS data, which are related to an efficient photogenerated charge separation (e–h+). Additionally, our results suggested that the hematite surface roughness and wettability should be considered as important parameters for producing active electrodes for solar water oxidation. A quasi-super hydrophilic surface observed for electrode sintered at high temperature and illustrated by contact angle images could be favoring solid/liquid interface to increase the surface efficiency for chemical reaction. Finally, this work gives a new insight into the role of high temperatures in the sintering process for the activation of pure hematite photoelectrode surface.