Writers: Yendry Regina Corrales Ureña, Paulo Noronha Lisboa-Filho, Michael Szardenings, Linda Gätjen, Paul-Ludwig Michael Noeske, Klaus Rischka

Keywords: Laccase; Maltodextrin; Hydrophobic; Bio-functionalization; Carbon

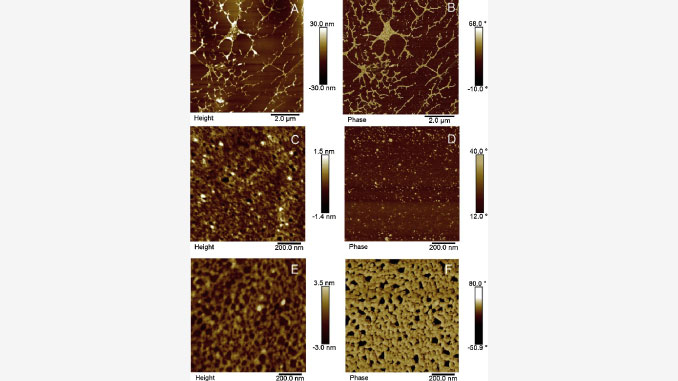

Abstract: A robust procedure for the surface bio-functionalization of carbon surfaces was developed. It consists on the modification of carbon materials in contact with an aqueous suspension of the enzyme laccase from Trametes versicolor and the lyophilization agent maltodextrin, with the pH value adjusted close to the isoelectric point of the enzyme. We report in-situ investigations applying Quartz Crystal Microbalance with Dissipation (QCM-D) for carbon-coated sensor surfaces and, moreover, ex-situ measurements with static contact angle measurements, X-ray Photoelectron Spectroscopy (XPS) and Scanning Force Microscopy (SFM) for smooth Highly Oriented Pyrolytic Graphite (HOPG) substrates, for contact times between the enzyme formulation and the carbon material surface ranging from 20 s to 24 h. QCM-D studies reveals the formation of rigid layer of biomaterial, a few nanometers thin, which shows a strongly improved wettability of the substrate surface upon contact angle measurements. Following spectroscopic characterization, these layers are composed of mixtures of laccase and maltodextrin. The formation of these adsorbates is attributed to attractive interactions between laccase, the maltodextrin-based lyophilization agent and the hydrophobic carbon surfaces; a short-term contact between the aqueous laccase mixture suspension and HOPG surfaces is shown to merely result in de-wetting patterns influencing the results of contact angle measurements. The new enzyme-based surface modification of carbon-based materials is suggested to be applicable for the improvement of not only the wettability of low energy substrate surfaces with fluid formulations like coatings or adhesives, but also their adhesion in contact with hardened polymers.