Writers: C. Aliotta and L.F. Liotta and V. La Parola and A. Martorana and E.N.S Muccillo and R. Muccillo and F. Deganello

Keywords: Samarium doped ceria; IT-SOFC; Solution combustion synthesis; Sintering in reducing atmosphere; Reducibility

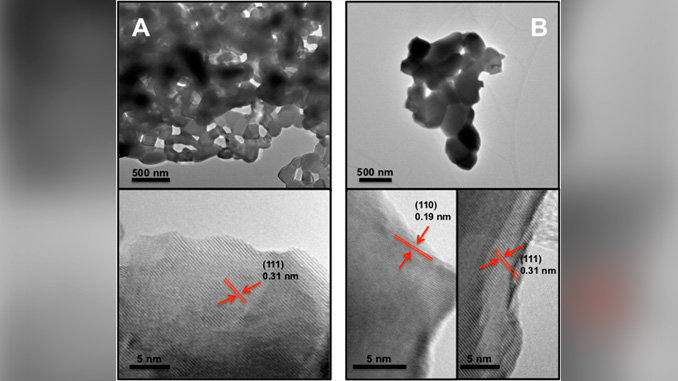

Abstract: Ce0.8Sm0.2O2 − x powders were synthesized by solution combustion synthesis using citric acid, cellulose and sucrose as single, or intimately mixed, fuels. The powders were characterized by X-ray diffraction, transmission electron microscopy, X-ray photoelectron spectroscopy, N2 sorption at −196 °C, H2-temperature programmed reduction and thermogravimetric analyses. Textural properties of the powders were shaped by the peculiar employed fuel. The study of reducibility revealed that oxygen vacancies formation is mainly influenced by both parameters, specific surface area and total pore volume. The different tendency toward reduction played a key role in sintering under reducing atmosphere (4% H2/Ar), and Ce0.8Sm0.2O2 − x prepared with sucrose showed, at scanning electron microscopy images, the highest average grain size. Impedance spectroscopy experiments in air disclosed different grain boundary resistances on the basis of synthesis fuel employed and, in particular, Ce0.8Sm0.2O2 − xprepared with sucrose exhibited the best electrical performance. Solution combustion synthesis thereby was able to tailor the morphological and reduction properties of Ce0.8Sm0.2O2 − x powders affecting even the microstructure of sintered pellet.