A versatile approach for the preparation of ceramics with porosity gradient: by using manganese and tin oxides as a model

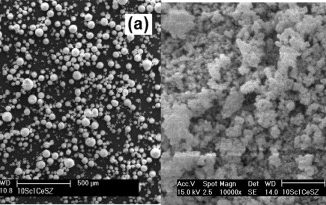

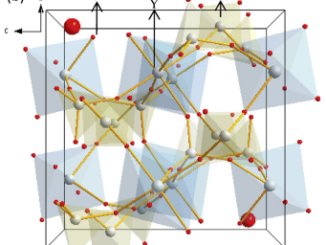

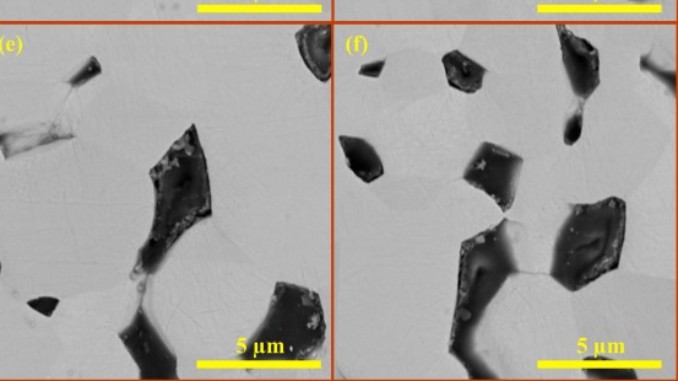

Abstract: Porous ceramics that exhibit porosity gradient are considered promising materials from the industrial point of view, especially for the production of ceramic membranes and filters. This paper describes a simple and versatile approach to produce ceramics with porosity gradient. In order to perform this study, MnO2/SnO2 bi-layered pellets were conformed via uniaxial pressure and sintered at 1100 °C and 1300 °C for different times. MnO2 layer had the role of sintering aid, while the SnO2layer was chosen as ceramic matrix subjected to the densification. The field emission scanning electron microscope (FE-SEM) was employed to obtain information on the microstructural features of these pellets. FE-SEM micrographs revealed that the overall percentage of porosity, pore size and shape in SnO2 layer can be controlled by sintering variables (temperature and time). The results indicated a correlation between the porosity gradient in SnO2 with the Mn concentration gradient in this matrix.

Authors: Júlio César Sczancoski & Edson Roberto Leite

Journal of the European Ceramic Society

Volume 38, Issue 4, April 2018, Pages 2027-2034

DOI: https://doi.org/10.1016/j.jeurceramsoc.2017.10.028