Computational design of cutin derivative bio-materials from fatty acids

Abstract: In recent decades, awareness for the preservation of the environment, promoted by government policies and international organizations, has intervened, amid other things, to encourage the use and massive development of green materials. Polyesters are one of the main groups among green materials, and synthetic products have been prepared using bio-reactors. On the other hand, biopolyesters such as cutin and suberin are abundantly and ubiquitously present in nature as tissues in higher plants. Cutin-inspired polymers and composites have been proven to be promising bio-materials, and some efforts have been employed both experimentally and theoretically to rationalize the physical-chemical principles underlying the self-assembly mechanisms that control the formation of such polymers in vivo. They have already been used to develop bio-materials with high biodegradability, biocompatibility, and non-toxicity. In particular, thin films have been synthetized to be applied in the can coating and packaging technology in the food industry. Other applications include tissue scaffolding, therapeutic uses, and molecular biomimetic recognition. Molecular simulation has become a valuable tool to gain insights at the atomistic level into the fundamental processes occurring in the synthesis of these bio-materials.

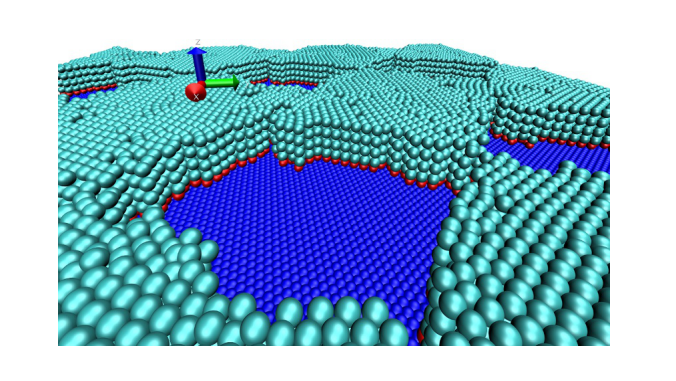

This chapter reports the latest advances combining atomistic simulations and atomic force microscopy (AFM) techniques to provide meaningful pieces of evidence on key features that control the self-assembly processes of different pure and mixtures polyhydroxy acids forming cutin.

Author(s): Bueno, O.V.M.; Benitez, J.J.; San-Miguel, M.A.

Green Chemistry and Computational Chemistry

Published: 2022

DOI: https://doi.org/10.1016/B978-0-12-819879-7.00001-5

CDMF

The CDMF, hosted at the Federal University of São Carlos (UFSCar), is one of the Research, Innovation and Dissemination Centers (RIDC) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council Scientific and Technological Development (CNPq), from the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).