Electrically conductive nanocomposites produced by in situ polymerization of pyrrole in pre-vulcanized natural rubber latex

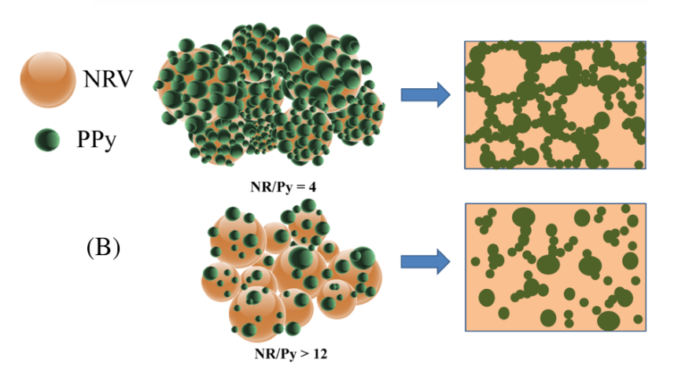

Abstract: Flexible conductive polymeric nanocomposites were produced by in situ polymerization of polypyrrole (PPy) in a natural rubber (NR) latex medium. Pre-vulcanized and non-pre-vulcanized NR latex, with varying NR/pyrrole (Py) monomer ratio was studied. The resulting nanocomposites were characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy, DC electrical conductivity, and mechanical properties. The electrical conductivity increased as the NR/Py ratio decreased reaching a maximum of 1.0 × 10−2 S/cm for a vulcanized nanocomposite with NR/PY = 4 mass ratio. In terms of mechanical properties, it was observed that tensile strength at break (σatbreak) also increased with decreasing of NR/Py mass ratio, and for the same proportion of Py, the nanocomposites obtained from vulcanized latex presented higher strength. SEM analysis revealed that unlike non-pre-vulcanized latex, PPy nanoparticles tend to be distributed in the pre-vulcanized matrix in circumferential patterns, with an average diameter of 1 micron, indicating that the rubber microparticles have been encapsulated by the conductive polymer. This engineered morphological structure has been shown to significantly influence the final properties of the nanocomposites, compared to those prepared from non-vulcanized latex, changing not only the distribution of PPy in the matrix, but also changing the coalescence behavior of NR particles, as well as influencing the percolation threshold.

Author(s): Santim, R. H.; Sanches, A. O.; da Silva, M. J.; McMahan, C. M.; Malmonge, J. A.

Polymer Composites

Published: 16 March 2022

DOI: https://doi.org/10.1002/pc.26591

CDMF

The CDMF, hosted at the Federal University of São Carlos (UFSCar), is one of the Research, Innovation and Dissemination Centers (RIDC) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council Scientific and Technological Development (CNPq), from the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).