Hydrophobization and odorization of wood for use in civil construction by immersion in nanoemulsions of tea tree and copaiba essential oil

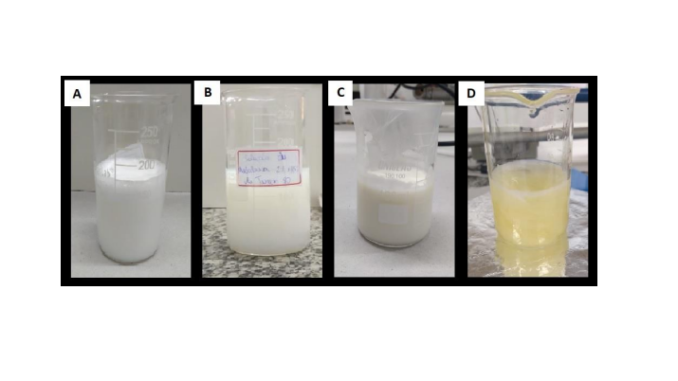

Abstract: Wood is a raw material from renewable source widely used by the construction industry due to its characteristics of easy handling and processability, good mechanical properties, sustainability, among others. Since it is a vegetal material, it is necessary to perform a preservative treatment before its application in civil construction. In this context, the search for new solutions as an option for biodegradable surface treatment to ensure the improvement of wood properties is one of the needs to be addressed so that the material performs well and increases its durability. Thus, treatments by immersion in emulsions of essential oils (EO) in the material, as an alternative to mitigate the occurrence of common pathologies in wood, proves to be a potentially innovative option for the furniture and construction industries. The present study aimed to evaluate the effects of hydrophobing and wood odorization treatments after the insertion of essential oils in nanoemulsion, emulsion, and pure oil conditions. The essential oils used were melaleuca (Melaleuca alternifolia) and copaiba (Copaifera officinalis), due to their antimicrobial, antifungal, antiseptic properties, and characteristic odor. The immersion application on the wood samples was conducted under the following conditions: 25% (w/w) melaleuca EO emulsion; 25% (w/w) copaiba EO emulsion; 2% (w/w) melaleuca EO nanoemulsion; 2% (w/w) copaiba EO nanoemulsion and the application of the same pure oils. The results showed that the suspension that presented the highest retention was the nanoemulsion, being OE of copaiba 44.10% and OE of melaleuca 40.41% in relation to the mass of the untreated sample. The emulsions resulted in 21.32% for OE copaiba and 20.51% for OE melaleuca, and in the pure oil condition, the observed retention was 15.11% for melaleuca OE and 23.82% for OE copaiba. The results obtained may be related to the hydrophilic characteristic of the wood, and the most aqueous suspension was the most absorbed. Through the Scanning Electron Microscopy (SEM) test it was possible to identify a uniform coverage of the samples for the pure oil, a rough aspect of coverage for the emulsion and a more cracked and dried surface in the samples with nanoemulsion. The contact angle test did not show a significant increase in hydrophobicity of the samples, with positive results from 7°±9° to 23°±15°, and in the nanoemulsion condition it decreased 12°± 9° compared to the untreated sample for copaiba EO and 16°± 9° for melaleuca EO, indicating a higher water permeability.

Author(s): Paixao, G. d. L. O.; Watanuki Filho, A.; Bonfim, K. S.; Aouada, F. A.; de Moura, M. R.

Materia-Rio De Janeiro

Published: 16 Jan 2022

DOI: https://doi.org/10.1590/S1517-707620220002.1320

CDMF

The CDMF, hosted at the Federal University of São Carlos (UFSCar), is one of the Research, Innovation and Dissemination Centers (RIDC) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council Scientific and Technological Development (CNPq), from the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).