Carbon Fiber Reinforced Polymer and Epoxy Adhesive Tensile Test Failure Analysis Using Scanning Electron Microscopy

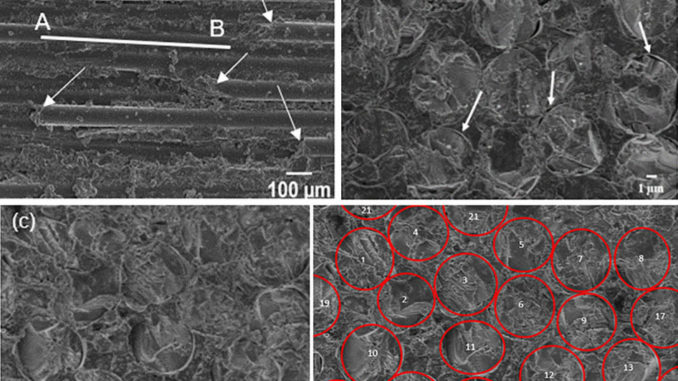

Abstract: Morphological characteristics analysis before and after tensile tests were studied using scanning electron microscopy (SEM) technique to follow the failure evolution on carbon fiber reinforced polymer (CFRP) and epoxy resins. Micrograph analysis of CFRP plate before tensile test shows some intrinsic manufacturing defects, which can influence the mechanical properties of the material. Micrograph analysis after tensile test shows that cracks propagation start in manufacturing defects, which lead the carbon fiber to be pulled out instead of breaking. Thus, cracks propagate through interfacial zones affecting the sharing force between matrix and carbon fiber. For the epoxies materials, the microscopy analysis showed that although epoxies adhesive have different phase distribution before tensile test, failure surfaces are described by fine granular particles covalent bonded with matrix, and the material fails in a brittle manner when the strength outstripped these bonds. Failure process for each material correlating the mechanical properties with the morphological characteristics of materials was discussed.

Materials Research-Ibero-American Journal of Materials

vol.20 no.4 São Carlos July/Aug. 2017 Epub July 06, 2017

Link: http://www.scielo.br/scielo.php?script=sci_arttext&pid=S1516-14392017000400951&lng=en&tlng=en

DOI: http://dx.doi.org/10.1590/1980-5373-mr-2017-0229