By Elton Alisson in São Carlos (Brazil) | Agência FAPESP – Nanometric silver particles with 32 times the bactericidal capacity of those currently in use are among the structures developed in the laboratories of the Center for Development of Functional Materials (CDMF), one of the Research, Innovation and Dissemination Centers (RIDCs) funded by FAPESP. CDMF is hosted by the Federal University of São Carlos (UFSCar) in São Paulo State, Brazil.

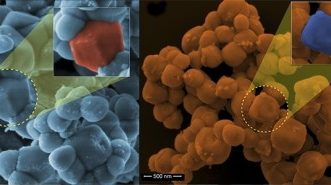

To create these and other innovative materials, CDMF researchers have developed a technique capable of identifying the ideal shape of nanoparticles (between 1 billionth and 100 billionths of a meter in size) designed to have specific properties or characteristics and of investigating how chemical methods, such as the application of solvents and additives or the control of pH (acidity), and thermal or other physical methods can modify the morphology of these nanomaterials.

Some of the results of studies performed using this novel technique were presented to the first Symposium on Research and Innovation in Functional Materials held by CDMF on May 23-34, 2019, at UFSCar.

“Our method enables us to model the different shapes a nanomaterial may take in the development of nanoparticles or nanocrystals with technologically interesting properties,” Juan Manuel Andrés Bort, who delivered a paper on the subject to the symposium, told Agência FAPESP. Bort is a professor at Spain’s Jaume I University and one of the creators of the technique.

As Bort explained, the emergence of nanotechnology has shown that atomic- and molecular-scale materials have different physical and chemical properties from those observed at the macrometric scale. This has enabled scientists to develop structures and materials with enhanced optical, catalytic, bactericidal and other properties.

Recent discoveries have shown that not only the small size but also the shape of nanoparticles is highly important, since most physical and chemical properties depend on the shape of a material.

“We realized that the morphology of a crystal or particle at the nanometric scale significantly influences its end-use in catalyst reactivity, bactericidal activity or sensor performance,” Bort said. “As a result, we saw that it’s necessary to characterize and control not just the size but also the shape of nanoparticles.”

To calculate the possible morphologies of a nanoparticle or nanocrystal and predict the ideal shape for the desired characteristics, researchers have followed an approach proposed for macrometric materials in 1901 by Russian crystallographer George Wulff (1863-1925).

According to the mathematical equation known as the Wulff construction, the equilibrium shape of a crystal can be predicted from the surface energy of its facets. The CDMF researchers applied this approach to nanoscience and combined it with computer modeling and simulation to develop a simpler way to predict the shape of nanoparticles with the desired properties based on surface energy.

“We succeeded in calculating nanomaterial morphologies in quantum terms and on that basis in developing a ‘map’ of the shapes that nanoparticles must have in order to present a property of interest,” Bort said.

In conjunction with high-resolution electron scanning microscopy, which is used to study microstructures at the atomic scale, this “map” of possible shapes of nanoparticles has been the basis for the development of several new materials in recent years. They include zinc tungstate (ZnWO4) and silver tungstate (α-Ag2WO4) nanocrystals with superior photoluminescent and photocatalytic properties.

“The method we’ve developed enables us to understand the evolution of the structural, electronic and magnetic properties of nanoparticles during continuous surface changes with precision, atom by atom,” Bort said.

Innovation award

Postdoctoral researcher Amanda Fernandes Gouveia, who earned her PhD from UFSCar with a scholarship from FAPESP, used the new method to evaluate the influence of reagents and temperature differences on the photocatalytic properties of zinc and silver tungstate.

In the case of zinc tungstate, for example, samples obtained at different temperatures had different photocatalytic properties even though the characteristics of the material were identical.

“It wasn’t possible to describe these surfaces experimentally, or to say which atoms and clusters were present,” Gouveia said. “The modeling method made description possible, relating temperature differences and the resulting surfaces to the observed catalytic activity.”

The study won an Innovation Award at Nano-Micro Conference 2018 in December in South Korea. The annual conference brings together experts, academicians, senior scientists, industry executives and project leaders from all over the world to discuss new developments and frontier research in the multidisciplinary field of nano-micro science and engineering.

Link to original article: http://agencia.fapesp.br/shape-influences-the-properties-of-nanomaterials/