By Elton Alisson – Agência Fapesp

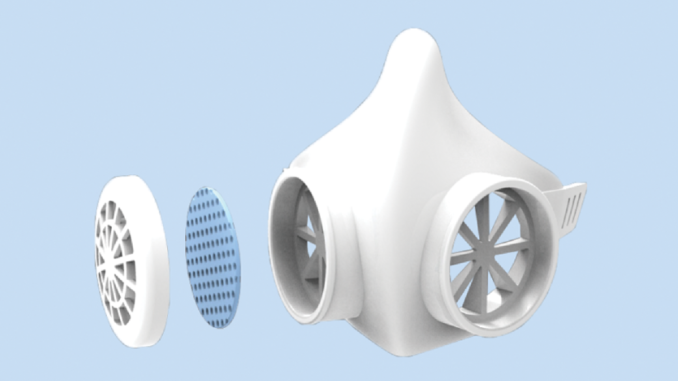

The São Paulo startup Nanox developed, in partnership with the plastics industry Elka, a reusable mask that promises to provide a higher level of protection against contamination by the new coronavirus (SARS-CoV-2), which causes the disease COVID-19. The equipment is made with a flexible polymer – similar to a rubber -, moldable to the contours of the face and with microparticles based on silica and silver, incorporated into the surface of the material.

Developed through projects supported by the Fapesp Innovative Research in Small Business Program (Pipe), of the São Paulo Research Foundation, the particles have antimicrobial properties.

“Silver and silica microparticles increase the level of protection by preventing the presence of fungi and bacteria in the mask, which can facilitate the adhesion and proliferation of the new coronavirus on the surface of materials”, says Luiz Gustavo Pagotto Simões, director at Fapesp from Nanox.

In order to guarantee protection against the virus, the mask is fully sterilizable by washing with soap and water before and after use. To protect the respiratory tract, the personal protective equipment has two disposable filters of the type PFF2, similar to the type N95 present in the masks currently used by health professionals.

The filters are inserted in respirators on the sides of the mask and protected by covers, which prevent physical contact and contamination by direct touch with the hands. The amount of material needed to produce the filters is also much less than that used to produce conventional masks, explains the manager.

“The time for replacing the filters will need to be established by the health services”, he ponders. According to Simões, the mask filters meet the requirements for suppliers of raw materials present in disposable absorbent products for external use, established in RDC 142 of the Ministry of Health.

Tests

The material also underwent bacteriological filtration efficiency tests (BFE) – which determine the efficiency of a product’s bacterial filtration -, reaching the minimum value of 95% required by the technical regulation for N95 type respiratory masks.

“The goal is to later obtain the material certification as PFF2, equivalent to N95. But the product can now be commercialized because, due to the pandemic of the new coronavirus, Anvisa [Agência Nacional de Vigilância Sanitária] relaxed the rules for manufacturing some products aimed at fighting COVID-19. This made it possible for Elka to manufacture the masks ”, explains Simões.

Initially, 200 thousand masks will be produced, whose unit cost is estimated between R $ 20 and R $ 30. The first units are expected to be delivered in early May. Elka intends to donate up to 10% of production to health institutions.

“We received six orders before the official product launch. The idea is to initially serve the national market and that the mask can be used not only by health professionals who are on the front line of care for patients with COVID-19, but by the population in general ”, says Simões.

The researcher points out that, although it has already been demonstrated that the silver and silica microparticles they produce have action against some types of viruses, there is still no evidence that they are capable of directly eliminating the new coronavirus. “Microparticles have the potential to act against the coronavirus. But we intend to carry out tests to prove this hypothesis ”, he says.

International connection

Representatives from Nanox and Elka met at International Entrepreneurship Center (IEC) – a business accelerator located in Boston, in the United States, where Nanox has a subsidiary.

Toy manufacturer, Elka was looking for a way to use idle part of its injection molding park to develop a product aimed at helping to combat COVID-19 and learned from IEC about the solutions developed by Nanox.

Spin off Nanox was created in 2004 from the Center for the Development of Functional Materials (CDMF), a Research, Innovation and Dissemination Center (CEPID), located at the Federal University of São Carlos (UFSCar).

The following year, the company submitted the first project to Pipe-Fapesp to develop deposition technology for silver nanoparticles in ceramic films and metallic materials, giving them anti-abrasive and bactericidal properties.

In 2011, with the product ready for the market, the company obtained funds from the Pappe / Pipe Program – a partnership between Fapesp and the Financier of Innovation and Research (Finep) – to scale the production of nanostructured antimicrobial particles.

In 2015, Pipe-Fapesp supported a new project of the company, the development of application of nanostructured fungicidal materials. In this trajectory, Nanox received resources from the Novarum Fund (Jardim Botânico Partners), won the Finep Technological Innovation Award in 2007 and won clients such as Taiff – manufacturer of hair dryers and plates -, São Carlos Carpets, Dabi Atlante, among others.

Acceleration

At the end of 2019, Nanox was one of 15 startups chosen from 1,000 companies from around the world to participate in the business acceleration program of Plug and Play, a global innovation platform based in Silicon Valley, in the United States.

Companies such as Dropbox, PayPal, Danger and Lending Club, among others, have participated in the Plug and Play acceleration programs. “Pipe-Fapesp’s support was fundamental in our trajectory”, says Simões.

For more information about the product, the interested party can access the website: https://www.otomask.com.br/.

CDMF

CDMF is one of the Research, Innovation and Dissemination Centers (Cepids) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council for Scientific and Technological Development (CNPq), linked to the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).