Writers: Milan Zunic; Goran Brankovic; Cesar Renato Foschini; Mario Cilense; Elson Longo; José Arana Varela

Keywords: Fuel cells; Anode; Cermet; Protonic conductor

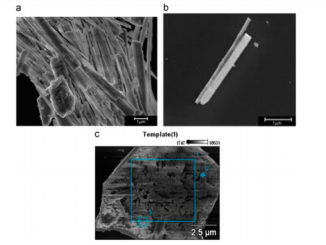

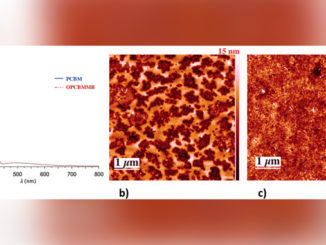

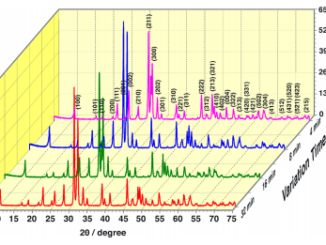

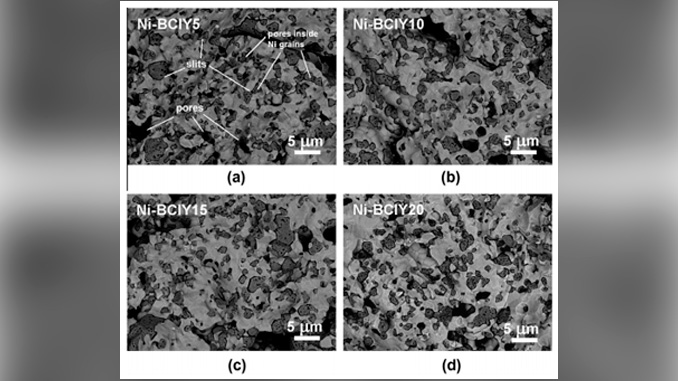

Abstract: Optimization of the major properties of anodes based on proton conductors, such as microstructure, conductivity and chemical stability, is yet to be achieved. In this study we investigated the influence of indium on the chemical stability, microstructural and electrical characteristics of proton conducting NiO–BaCe0.9−xInxY0.1O3−δ (NiO–BCIYx) anodes. Four compositions of cermet anode substrates NiO–BCIYx were prepared using the method of evaporation and decomposition of solutions and suspensions (EDSS). Sintered anode substrates were reduced and their microstructural and electrical properties were examined before and after reduction as a function of the amount of indium. Anode substrates tested on chemical stability in the CO2 atmosphere showed high stability compared to anode substrates based on commonly used doped barium cerates. Microstructural properties of the anode pellets before and after testing in CO2 were investigated using X-ray diffraction analysis. Impedance spectroscopy measurements were used for evaluation of electrical properties of the anode pellets and the conductivity values of reduced anodes of more than 14 S cm−1 at 600 °C confirmed percolations through Ni particles. Under fuel cell operating conditions, the cell with a Ni–BCIY20 anode achieved the highest performance, demonstrating a peak power density 223 mW/cm2 at 700 °C confirming the functionality of Ni–BCIY anodes.