AC Electric Field Assisted Pressureless Sintering Zirconia: 3mol% Yttria Solid Electrolyte

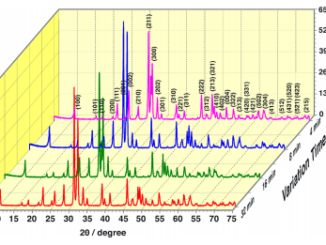

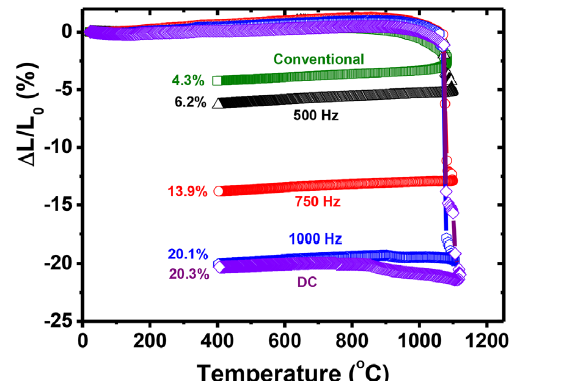

Abstract: 3 mol% yttria ionic conductors are sintered by applying AC electric fields with frequencies in the 0.5–1.0 kHz range at 1100 °C. The sintering experiments are conducted in pressed pellets positioned between platinum electrodes inside a dilatometer furnace. The dilatometer is modified in order to allow for the simultaneous monitoring of thickness shrinkage, electric voltage, and current across the pellet. The results show that the higher the frequency of the electric field, the higher the attained shrinkage and the apparent density of the pellets. Increasing the frequency of the applied electric field leads to an increase in the Joule heating promoted by the electric current pulse through the polycrystalline ceramic sample. A higher frequency therefore leads to higher amount of thermal energy delivered to the sample, favoring enhanced densification. The ionic resistivity decreases in pellets sintered with increasing frequency of the applied electric field. We suggest that Joule heating favors pore elimination and the removal of chemical species at the space charge region, inhibiting the blocking of oxide ions at the interfaces.

Author(s): Carvalho, S. G. M.; Muccillo, E. N. S.; Muccillo, R.

Physica Status Solidi a-Applications and Materials Science

Volume: 215 Issue: 6 Published: 2018

DOI: https://doi.org/10.1002/pssa.201700647

PDF: AC Electric Field Assisted Pressureless Sintering Zirconia 3mol% Yttria Solid Electrolyte