Mechanical, thermal, and morphological properties of natural rubber/45S5 Bioglass (R) fibrous mat with ribbon-like morphology produced by solution blow spinning

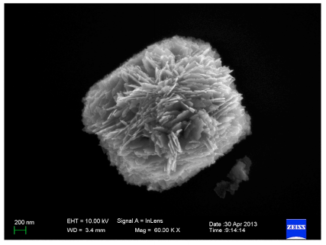

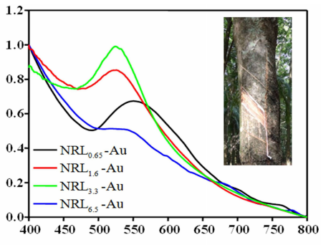

Abstract: Natural rubber (NR)/45S5 Bioglass (R) (BG) based fibrous mat biocomposite were fabricated using a solution blow spinning (SBS) method. NG/BG fibrous mat with ribbon-like morphology were obtained with different amounts of 45S5 BG to NR. Biocomposites exhibited uniform diameter distribution of fibers in the 40-60 mu m range. The preparation method and dispersion of particles in the NR matrix had significant influence on the final mechanical properties of the biocomposite, i.e., the tensile strength of membrane samples increased, while the elongation decreased compared to those of neat NR films. The glass transition temperature (T-g) value of the biocomposite samples shifted toward higher temperatures due to the movement restriction of the NR chains caused by the BG particles. For the biocomposite samples T-g was in the range of -30 to -28 degrees C, whereas for the NR film and NR fibrous mat T-g was -46.7 and – 40.5 degrees C respectively. The Cole-Cole plot was an imperfect semicircle indicating the heterogeneity of the system as well as the adequate interaction between BG and NR. The production of membrane biocomposites with good thermal and mechanical properties employing the SBS method could be promising and potential for biomedical applications.

Author(s): Sousa, EA; Silva, MJ; Sanches, AO; Soares, VO; Job, AE ; Malmonge, JA

EUROPEAN POLYMER JOURNAL

Volume: 119 Pages: 1-7 Published: OCT 2019

DOI: 10.1016/j.eurpolymj.2019.07.002