Writers: Michael J. Brennan; Walter Katsumi Sakamoto; José Antônio Malmonge; Marcelo Ornaghi Orlandi

Keywords: Structural health monitoring; Nanocomposite; Continuous sensors; Neural network; ITO

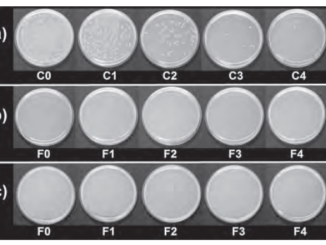

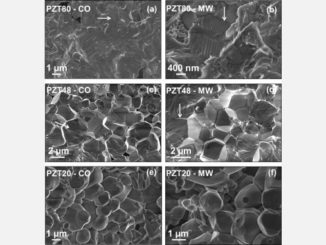

Abstract: In order to secure the structural integrity of aeronautic structures, several structural health monitoring techniques have been studied throughout history. One of the most recent technologies developed involves the use of continuous sensors, made of thin films of nanocomposite material. Previous works proved that the ITO/PMMA nanocomposite sensor (ITO—indium tin oxide) nanobelts inserted in a matrix of PMMA (poly(methyl methacrylate)) was capable of detecting a certain damage by comparing the values of resistances between two points before and after the damage occurrence, however some uncertainties were found. Two problems were found during the development of the sensors: first of them was the difficulty to obtain uniformity of the coating material through its monitored area and; the second one was the influence of environmental changes on the measurements. The uniformity problem was solved by enhancing the nanocomposite synthetizing method, which resulted in more constant readings of resistances, although there were still variations on measurements taken on different days. To verify the cause of this oscillation, several tests were performed in an environmental chamber, in which the temperature and the humidity were controlled during the measurements, making it possible to find out which parameter would cause more changes on the readings.