Femtosecond-laser processing incubation in Diamond-like carbon

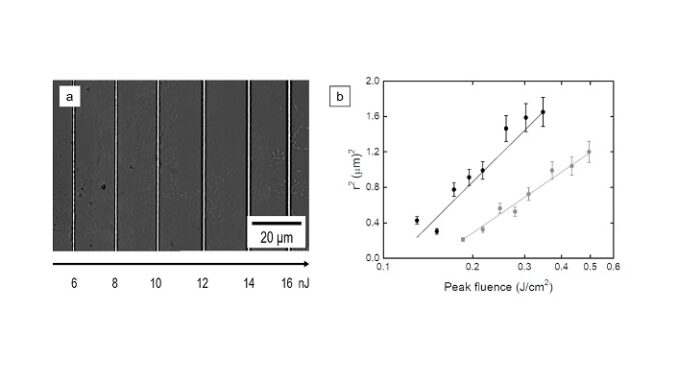

Abstract: Diamond-like carbon (DLC) has been commercialized as an advanced material for combining diamond and graphite properties with other material systems, with ease of processing and reduced costs. DLC has been broadly studied as an interesting material for applications ranging from biology to optics, passing through mechanics and electronics. Hence, for given applications, complex patterning of DLC is required, which can be accomplished by conventional lithographic approaches, as well as laser structuring. In this way, this paper focuses on studying the incubation process, the dependence of the threshold fluence with the number of irradiated pulses, on the fs-laser microstructuring of DLC films. We determined a single pulse fluence of (1.0 ± 0.1) J/cm2, a value that decreases to a plateau of (0.13 ± 0.04) J/cm2 for a large number of pulses. The slow evolution of the fluence threshold with the number of pulses indicates a low incubation parameter, such that a large number of pulses is required to damage the material. By modeling the single-pulse damage threshold fluence considering multiphoton and avalanche ionization, we were able to estimate a two-photon absorption cross-section for DLC of (1.5 ± 0.5)

10−60 m4s1photon−1, which is consistent with the one known for diamond. Finally, Raman spectroscopy of the fs-laser processing DLC sample indicates a decrease of the sp3 fraction and a more ordered phase.

Author(s): Nolasco, L. K.; Almeida, F. P.; Almeida, G. F. B.; Almeida, J. M. P.; Mastelaro, V. R.; Paula, K. T.; Mendonca, C. R.

Optical Materials

Published: April 2022, Volume 126, 112203

DOI: https://doi.org/10.1016/j.optmat.2022.112203

CDMF

The CDMF, hosted at the Federal University of São Carlos (UFSCar), is one of the Research, Innovation and Dissemination Centers (RIDC) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council Scientific and Technological Development (CNPq), from the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).