Improving nitrate-to-ammonia conversion efficiency on electrodeposited nickel phosphide via surface δ-FeOOH modification

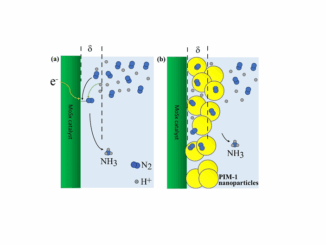

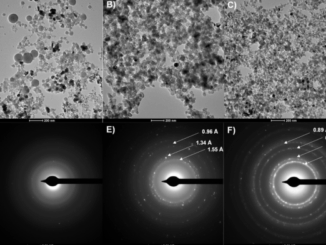

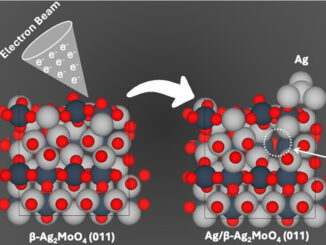

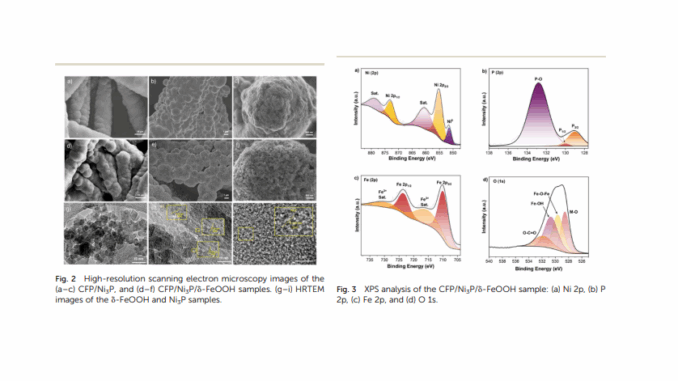

Abstract: Electrocatalytic nitrate reduction to ammonia is an appealing and promising approach for recovering industry and agricultural wastewater. However, there is a lack of efficient electrocatalysts for NO3− conversion at low overpotentials and a range of nitrate concentrations, which could enable nitrogen recovery from various wastewater streams. Here, we report an affordable and efficient electrodeposited amorphous-Ni3P electrode modified with δ-FeOOH, forming a heterojunction catalyst that efficiently converts nitrate into ammonia. The optimum heterojunction performance achieved a high faradaic efficiency of 98% ± 0.72 at −0.3 V vs. RHE with an NH3 production yield of 8.49 mg h−1 cm−2, ranking Ni3P/δ-FeOOH among the most active electrocatalysts so far reported for this process. Ni3P/δ-FeOOH showed good stability using ethyl cellulose as a green and fluoride-free binder without losing the superficial modification. Mechanistic studies by in situ Raman spectroscopy show that the role of δ-FeOOH is the stabilisation of the NOx intermediates. At the same time, Ni3P provides *H species available for NOx reduction, thus resulting in highly selective NO3 hydrogenation. In contrast, in the absence of δ-FeOOH, Ni3P exhibits significantly lower NH3 faradaic efficiency due to simultaneous H2 evolution. Therefore, the present results show the synergistic effect between δ-FeOOH and Ni3P in the electrocatalytic nitrate reduction, with δ-FeOOH playing a crucial role in stabilising the reaction intermediates and enhancing the ammonia selectivity.

Author(s): Anelisse B. Silva, Eduardo A. Reis, Jiajun Hu, Josep Albero, Caue Ribeiro, Lucia H. Mascaro and Hermenegildo García

J. Mater. Chem. A

First published 02 Jan 2025

DOI: https://doi.org/10.1039/D4TA04511D

CDMF

The CDMF, hosted at the Federal University of São Carlos (UFSCar), is one of the Research, Innovation and Dissemination Centers (RIDC) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council Scientific and Technological Development (CNPq), from the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).