Writers: A. M. Rosa; E. P. da Silva; M. ChavesL. D. Trino; P. N. Lisboa-Filho; T. F. da Silva; S. F. Durrant; and J. R. R. Bortoleto

Keywords: rf-Magnetron sputtering; Structural transitions; Substrate temperature; Transmittance measurements; Magnetron sputtering; Optical films; Optical properties; Substrates; Surface morphology; Zinc oxide; Metallic films

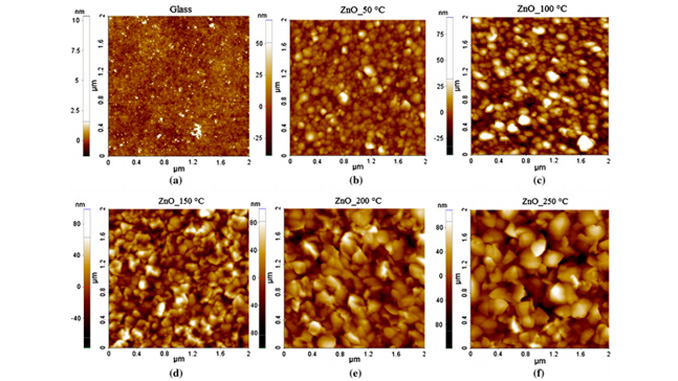

Abstract: Zinc oxide (ZnO) thin films were prepared using reactive radio-frequency magnetron sputtering of a pure metallic zinc target onto glass substrates. The evolution of the surface morphology and the optical properties of the films were studied as a function of the substrate temperature, which was varied from 50 to 250 °C. The surface topography of the samples was examined using atomic force microscopy (AFM), and their optical properties were studied via transmittance measurements in the UV–Vis–NIR region. DRX and AFM analyses showed that the surface morphology undergoes a structural transition at substrate temperatures of around 150 °C. Actually, at 50 °C the formation of small grains was observed while at 250 °C the grains observed were larger and had more irregular shapes. The optical gap remained constant at ~3.3 eV for all films. In the visible region, the average optical transmittance was 80 %. From these results, one can conclude that the morphological properties of the ZnO thin films were more greatly affected by the substrate temperature, due to mis-orientation of polycrystalline grains, than were the optical properties.