Writers: D.B. Istuque and L. Reig and J.C.B. Moraes and J.L. Akasaki and M.V. Borrachero and L. Soriano and J. Payá and J.A. Malmonge and M.M. Tashima

Keywords: Alkali-activated binder; Microstructure; Residue; X-ray techniques

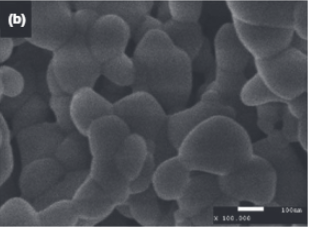

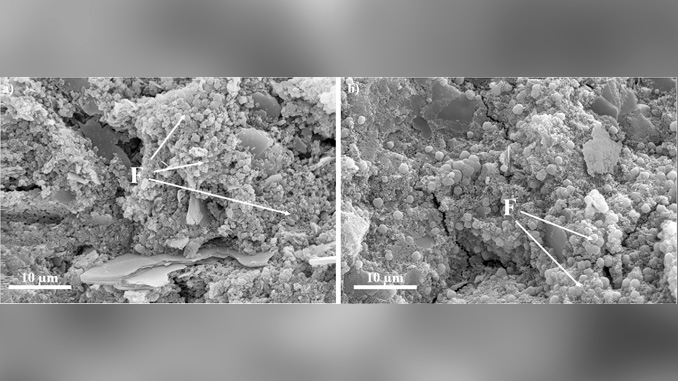

Abstract: In recent years, geopolymers have become a widely researched binding material. There are technological and environmental advantages to using this type of binder instead of Portland cement. In this study, binary systems of geopolymers were produced by using mixtures of metakaolin (MK), a well-known aluminosilicate raw material, and a residue from sewage sludge incineration: sewage sludge ash (SSA). This ash was used to partially replace the metakaolin in proportions of 0–20%. The mixtures were activated with alkaline solutions and they were cured by using two different conditions: at room temperature (25 °C) and in a thermal bath (65 °C). The samples were assessed by X-ray diffraction, scanning electron microscopy (pastes) and compressive strength (mortars). The results from these studies showed zeolite formation (faujasite) in geopolymers cured in the thermal bath, which caused a decrease in the compressive strength of the alkali-activated mortars. Replacement of MK with SSA caused a lower reduction in the compressive strength of mortars cured at 65 °C. However, at room temperature, similar mechanical strength was observed for the MK and MK-SSA systems. These results demonstrated that SSA is a suitable mineral precursor for partial replacement of MK in geopolymer production.