Synthesis of Y2BaCuO5 nano-whiskers by a solution blow spinning technique and their successful introduction into single-grain, YBCO bulk superconductors

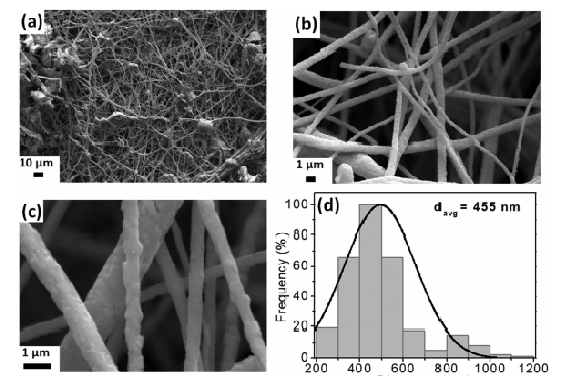

Abstract: The ability of single grain Y-Ba-Cu-O (YBCO) bulk superconductors to trap large magnetic fields is due generally to the presence of embedded, non-superconducting Y2BaCuO5 (Y-211) phase particles, in optimum amount, in the superconducting YBa2Cu3O7-delta (Y-123) phase matrix, which increases flux pinning and, hence, critical current density of the bulk material. The presence of smaller particles of Y-211 could be expected to improve further the superconducting properties of single grain, bulk YBCO samples, although the smallest Y-211 particles that have been engineered to date within the bulk microstructure are around 800 nm in size. It is extremely challenging to reduce the Y-211 particle size any further due to problems of particle agglomeration that originate, inevitably, from the effects of surface energy and reactivity at relatively high processing temperatures. In this work, we report a novel approach to the fabrication of Y-211 pinning centres in bulk YBCO superconductors in the form of nano-whiskers manufactured by a solution blow spinning technique. The Y-211 nano-whiskers, of which 62% were smaller than 500 nm, were added to the YBCO precursor powders to produce a single grain bulk sample by the buffer-aided top-seeded melt growth (BA-TSMG) processing technique. The resulting YBCO single grain, of diameter 20 mm, was able to trap a magnetic field of 0.63 T at 77 K with an associated critical current density of 3.9 x 10(4) A/cm(2) in self-field. The results of this study demonstrate clearly that the use of Y-211 nano-whiskers is a promising route for enhancing flux pinning in bulk YBCO single-grains, which is potentially significant for the development of high field engineering applications.

Author(s):Rotta, M; Namburi, DK; Shi, YH; Pessoa, AL; Carvalho, CL; Durrell, JH; Cardwell, DA; Zadorosny, R

CERAMICS INTERNATIONAL

Volume: 45 Pages: 3948-3953 Published: FEB 15 2019

DOI: 10.1016/j.ceramint.2018.11.068