The Influence of Annealing on the Sb Layer in the Synthesis of [001]-Oriented Sb2Se3 Film for Photoelectrochemical Hydrogen Gas Generation

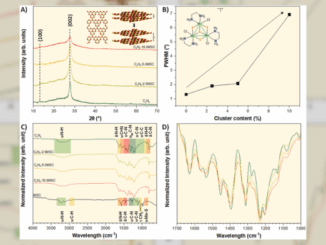

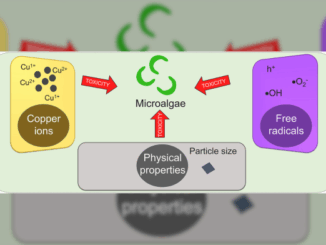

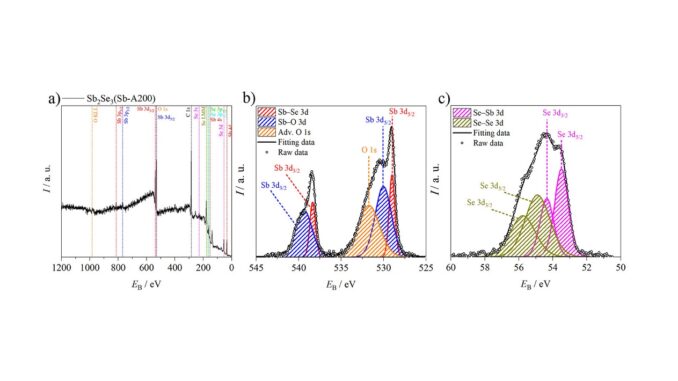

Abstract: This work reports a new thermal treatment approach to obtain [001]-oriented Sb2Se3 film, which consists of preliminary annealing of the Sb layer before its selenization. Among the different Sb annealing temperatures assessed, the one at 200 °C followed by selenization (Sb2Se3(Sb-A200)) results in a considerably high texture coefficient at the [001] direction, whereas the Sb2Se3 film obtained only by selenization of the non-annealed Sb film (Sb2Se3(Sb-NA)) features preferential orientation at the [hk0] direction. In terms of photoelectrochemical (PEC) performance for H2 generation, the Sb2Se3(Sb-A200)/CdS/TiO2/Pt film delivers a substantial photocurrent density of −5.65 mA cm−2 at 0 VRHE, which is 10 times higher compared to the Sb2Se3(Sb-NA)/CdS/TiO2/Pt film. Additionally, the employment of the Sb annealing step results in stable PEC performance of the Sb2Se3 film over 7000 s, meaning that the photocorrosion is minimized. The improved PEC performance of the Sb2Se3 film is attributed to better crystallinity and composition closer to the stoichiometric condition, as well as the preferential orientation at the [001] direction that favors charger carriers’ transportation. At last, the findings of this work feature an innovative thermal treatment approach to obtain [001]-oriented Sb2Se3 film to further improve H2 generation from PEC water splitting.

Author(s): Magno B. Costa, Moisés A. de Araújo, Joaquim Puigdollers, Pablo Ortega, Teresa Andreu, Cristobal Voz, Edgardo Saucedo, Lucia H. Mascaro.

Adv. Funct. Mater

First published: 17 April 2025

DOI: https://doi.org/10.1002/adfm.202506401

CDMF

The CDMF, hosted at the Federal University of São Carlos (UFSCar), is one of the Research, Innovation and Dissemination Centers (RIDC) supported by the São Paulo State Research Support Foundation (Fapesp), and also receives investment from the National Council Scientific and Technological Development (CNPq), from the National Institute of Science and Technology of Materials in Nanotechnology (INCTMN).