Writers: L. Pérez-Acosta and E. Govea-Alcaide and J.G. Noudem and I.F. Machado and S.H. Masunaga and R.F. Jardim

Keywords: Cuprates superconductors; Texture; Spark-plasma; Anisotropy

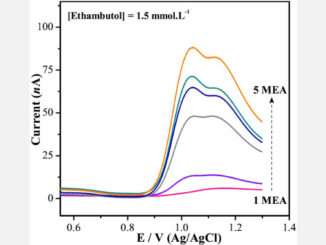

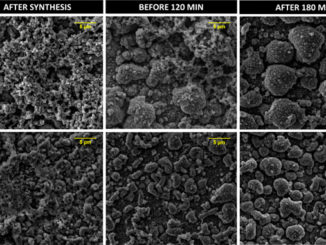

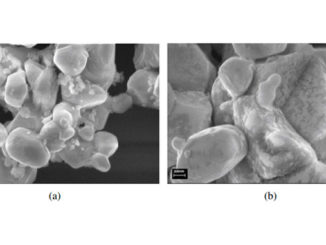

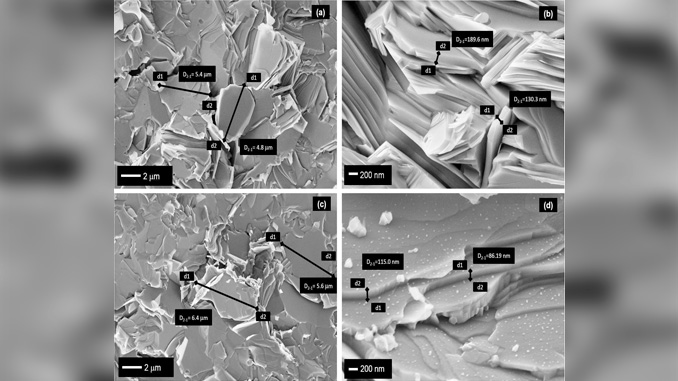

Abstract: Consolidated powders of the superconducting cuprate Bi1.65Pb0.35Sr2Ca2Cu3O10+δ (Bi-2223) by the spark-plasma texturing (SPT), spark-plasma sintering (SPS), and the traditional solid-state reaction method were investigated by several techniques and their features compared. The results show that SPT samples exhibit a higher degree of texture, as inferred by a Lotgering factor of ∼0.73 along the [00l] direction and a relative density of 96% of the theoretical value. From magnetic hysteresis loops M vs. H at 5 K, the intragranular critical current densities along two applied magnetic field orientations, ![]() and

and ![]() , relative to the compacting pressure direction, were determined. The anisotropy factor,

, relative to the compacting pressure direction, were determined. The anisotropy factor, ![]() , yielded an estimate of ∼2 in the SPS sample and ∼19 for samples obtained via the SPT method. In the latter samples,

, yielded an estimate of ∼2 in the SPS sample and ∼19 for samples obtained via the SPT method. In the latter samples, ![]() at 5 K is close to 1.3×108 A/cm2, a value higher than others found for the same compound. The temperature dependence of the electrical resistivity, ρ(T), analyzed within the framework of a current conduction model for granular superconductors, supports the higher degree of texture of SPT samples and indicates changes in the oxygen content when samples are subjected to a post-annealing heat treatment. All the results reveal the promising capabilities of the SPT method for improving volume density, texture, and grain boundary connectivity of superconducting Bi-2223 materials.

at 5 K is close to 1.3×108 A/cm2, a value higher than others found for the same compound. The temperature dependence of the electrical resistivity, ρ(T), analyzed within the framework of a current conduction model for granular superconductors, supports the higher degree of texture of SPT samples and indicates changes in the oxygen content when samples are subjected to a post-annealing heat treatment. All the results reveal the promising capabilities of the SPT method for improving volume density, texture, and grain boundary connectivity of superconducting Bi-2223 materials.