Writers: M. Congiu, F. Decker, D. Dini 2, C. F. O. Graeff

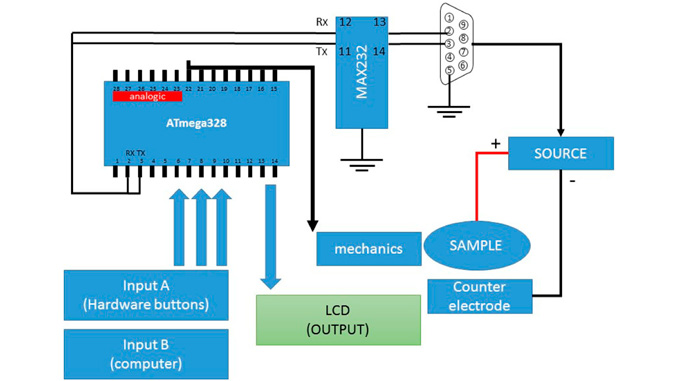

Keywords: SILAR; Successive ionic layer adsorption and reaction; Dip coating; Electrodeposition; Open source; GNU equipment

Abstract: A reliable and cheap equipment is hereby proposed for the deposition of thin films on several substrates. This system is capable of deposition using three different techniques sequentially on the same substrate. The techniques available are ionic layer adsorption and reaction (SILAR), electrodeposition, and dip coating on both rigid and flexible conductive substrates (FTO, ITO-PEN). Using low-cost electronic components, we built a working prototype, driven by a simple software that is open source and user-friendly. In order to test our system, we used it to fabricate dye-sensitized solar cells (DSSCs) and counter electrodes of platinum and cobalt sulfide using both rigid glass-FTO and flexible ITO-PEN substrates. The electrodes as well as the complete devices have been characterized through cyclic voltammetry (CV). The solar cell devices have been characterized through current versus voltage curves (I–V) under simulated solar illumination.