Writers: Reginaldo Muccillo, Eliana N.S. Muccillo

Keywords: Flash sintering; Tin dioxide

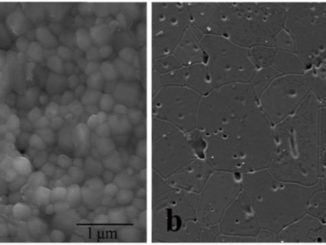

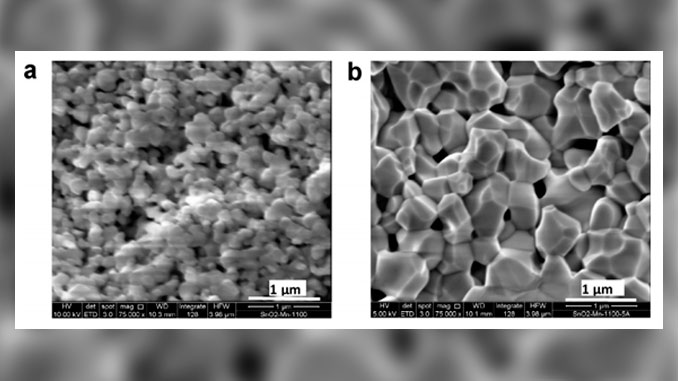

Abstract: SnO2 green pellets were submitted to ac electric fields at temperatures below 1350 ◦C. Electric current pulses occurred and a substantial modification wasfound in the microstructure of the pellets after application of 80 V cm−1 at 900, 1100 and 1300 ◦C. Similar experiments were carried out in SnO2 mixed to 2 wt.% MnO2. The linear shrinkage of the pellets was monitored with a dilatometer during the application of the electric field. Scanning electron microscopy micrographs of the pellets show the grain structure evolution after the electric current pulses. The larger is the electric current flow through the SnO2 pellet, the larger are the shrinkage and the average grain size. Even though sintering occurs without significant densification in SnO2, the welding of the grains is evident. The apparent density of green pellets of SnO2 with MnO2 addition sintered at 1100 ◦C increased 110% with the application of 80 V cm−1.